Quad to the Core

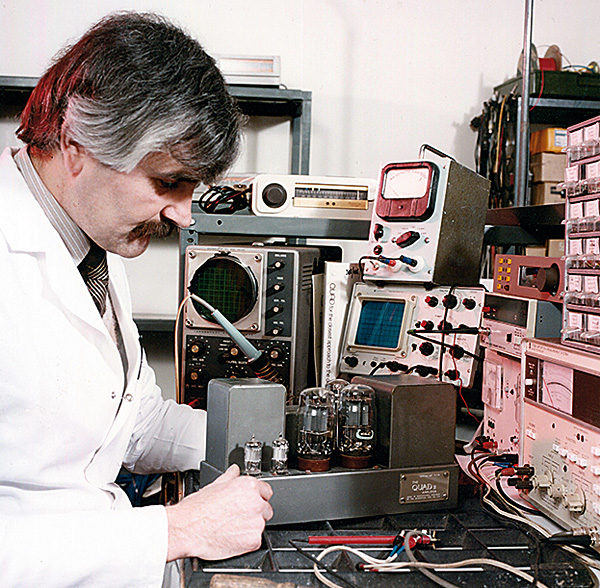

It was 15 years since I had interviewed Ken Bunting, in charge of Quad's service department, but back then it was to pick his brains about the company's history. Early this May, I had the privilege of repeating the interrogation, on the occasion of Ken's retirement. Off to the wilds of Cambridge, where I found him on his last day, in a busy-as-ever service area with everything from Quad ESL63s to valve units being repaired – contrary to any rumours or worries that the company had abandoned its legendary back-up division.

Ken started at Quad on the 16th of March 1970. 'It was my first job in audio, hired as a Service Engineer. I'd trained with Pye Philips, so I was in communications, working with RF, so my first real job with the company was to work on AM tuners and tuner alignment. There was no service department in 1970 – that was being set up. I was head-hunted really: they were just starting the department. They were still building the room.'

Ken answered to the works manager, Jim Watson. 'Peter Walker was in and around the place all of the time. He was that sort of character and could talk to anybody – a very easy-going person. I was a sprout of 21, I'd had a five-year apprenticeship with Pye, and I had one year working with them when my apprenticeship finished, but that was going nowhere.

'I was too valuable on production, but I wanted other challenges. The only way to move on was to leave, although they don't want you to leave because they put all the investment into training you! So that's why I came to Quad, as they were setting up the service department, and because I quite liked mending things for people.'

Ducking 'n' Diving

Over his 48 years, Ken worked on everything bar the ESLs. He laughs, 'I ducked and dived that. That was for somebody else! It wasn't that I didn't know how it works, it wasn't that I couldn't make it – it was just that it just never appealed to me. I liked the sound of a pair of them, but it just didn't appeal.'

Amid all the work with preamps and power amps, Ken's speciality was tuners. Although trained in this area, he said that the service department didn't get involved directly in the designs, though their suggestions – derived from hands-on experience after the fact – were taken into consideration. These may have included only small detail changes, but they were incorporated into the products, especially if cost-effective.

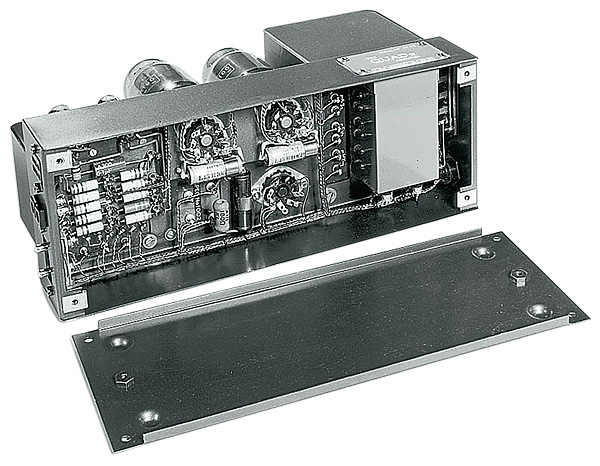

'At the end of the day, Peter wanted to make money, and he was quite a clever man at making money as easily as he could. That's why the main amp [the Quad II] was so simple because we knew full well that the way to do it was to split that cathode and bias resistor into two for each valve and to do it that way. He could build two amps with that single ballast resistor and saved money on that. He was very shrewd.'

Above all the cost savings, quality remained paramount. Says Ken, as an example, 'I think it nearly killed him, developing that output transformer because it had the cathode feedback windings in there, and it was very difficult doing the maths for the transformer. And later on, when we had the kit that could measure it properly, that showed how good it really was. And all from working only with slide rules.'

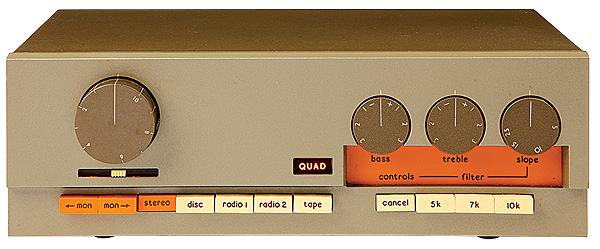

It was no surprise when asked to name his favourite among all of the models he'd worked on, Ken said, 'They've all got little idiosyncrasies, as regards to working, and some are easy, like the 33, but then the 34 could suffer component failures and things. That sets up a challenge.

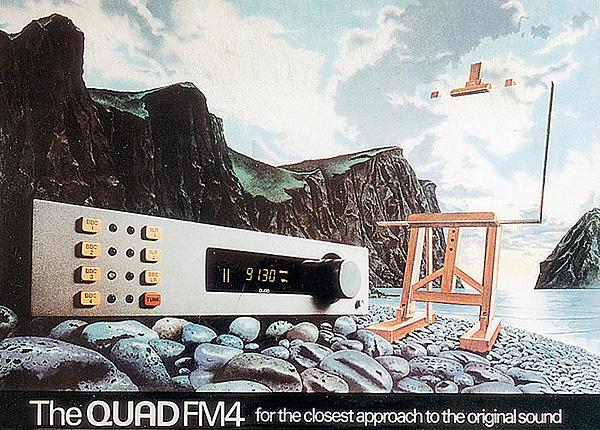

'But if I think deep down for a really nice unit, it's hard to beat the the FM4. It had its battery problems, but for what I'm doing, I go through the RF section, then the audio section, and the quality you get out of an FM broadcast is excellent. But FM is slowly disappearing, so we don't make an FM tuner anymore.'

All Change

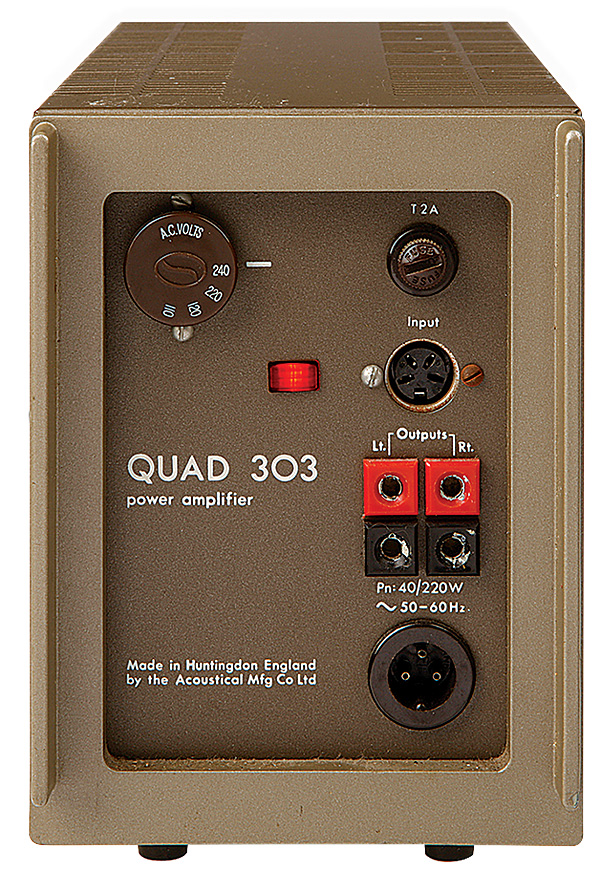

When Ken arrived, the ESL57 was still being produced and the 33/303 pre/power amp combination was in production, 'but the 303 had suffered problems in that initial run, so we started at around Serial Number 1000, and we were up to about 19,000 when we changed the style of the board. Then from 19,000 to 100,000, it never changed, so all that lot was the same.'

Ken joined during a period of momentous upheaval in the audio industry, while the transition from valves to solid-state was still underway, and the mono valve Quad II amplifier was in production while the 303 stereo power amplifier was establishing itself as the company's first transistor product.

'The main amplifiers [Quad IIs] were the bread-and-butter, but there were slight problems with the 303. While they sorted out the problems, they got the girls to build the main amplifiers because a lot of people still had mono kit, or they had 22s, and they needed the extra power amp [to go stereo].

'So they did carry on and you can always tell the later ones because they had a metal serial number [badge] on them instead of the plastic one. Any Quad IIs with a metal plate are ones that were built while we were also making 33/303s.'

Quad was one of the companies that waited before committing entirely to solid-state design, avoiding the pitfalls that befell manufacturers who were early adopters. But Ken says it wasn't the transistors themselves that were the big problem.

'It was the circuitry that they finally sorted out,' he says. 'I think that the devices, and their selection, were all OK. Without a doubt, it was how they were used that caused the problems.

'The other kit we were making included the AM3 tuner – we only ever made a valve one, we never did do a solid-state AM tuner. We also had the FM2 which was still built because the FM3 didn't arrive until about 1971 to match in with it. The FM2 looked like a transistor one, but it wasn't – it was a hybrid.'