Sony PS-X800 Turntable

When it came to Lilliputian LP players Sony was late to the party, but is this early '80s deck with two motors and a tangential arm now an overlooked gem? We find out...

When it came to Lilliputian LP players Sony was late to the party, but is this early '80s deck with two motors and a tangential arm now an overlooked gem? We find out...

The 'small and square' turntables that appeared in the early 1980s were arguably the last important development in vinyl playback before CD arrived. Begun by Technics in 1979 with its SL-10 [HFN Apr '19], Japan's hi-fi industry rushed to produce something similar, with varying degrees of success.

It is odd that Sony, masters of cramming quarts of technology into pint-sized boxes, chose to excuse itself from this particular craze. Its 'very small and square' PS-Q7 [HFN Apr '21] was certainly neat, but it could not compete with the SL-10 and its imitators on performance. Meanwhile, a slew of drawer-loading models, such as the Sony PS-FL7 [HFN Mar '20], were niche products largely confined in appeal to the stack systems they matched.

Baby Bio

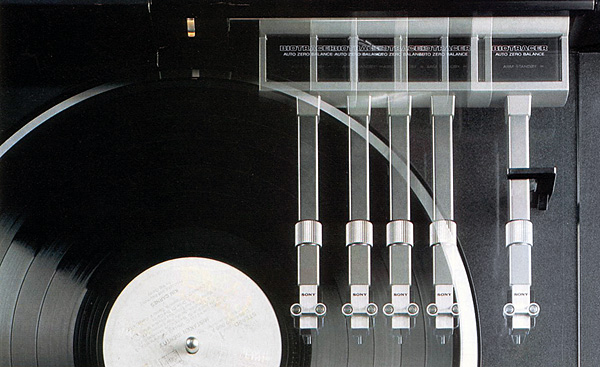

The closest Sony came to addressing 'small and square' head-on was with its PS-X800 Linear Biotracer turntable, launched in 1982 and seen here. Despite not being especially small, the PS-X800 did include other key features of the genre, such as a quartz-locked direct-drive motor, fully automatic operation and linear tracking. What's more, Sony's electronically damped Biotracer arm was also employed for the first time in a linear-tracker. The Biotracer system has been seen in these pages before as part of the PS-B80 [HFN Jul '12], the first Sony model to employ the technology.

To assist its tracking over warped records and through eccentric grooves, the Biotracer arm uses electromagnetic sensors to detect movement at the pivot in both the vertical and horizontal planes. Magnetic actuators gently assist the arm, maintaining a constant tracking force, without interrupting the slower movement of the stylus across the record. Resonances are damped, but higher, musical frequencies are unaffected. The effect can be appreciated by trying to move the headshell while the system is active: it feels like it's moving through a viscous liquid!

In theory this provides an ideal platform on which to mount the cartridge and extract the maximum information from the record groove. Furthermore, as Sony's Biotracer arm applies downforce electromagnetically, rather than by conventional static weights or springs, the tracking weight may be adjusted and optimised 'on the fly' between 0.5-3.0g, even as a record is being played.

A Cut Above

The linear-tracking aspects of the arm appeared conventional, but as ever with Sony there were refinements just beneath the surface. The arm was driven along a precision-ground bar by a tensioned cord, the same method used by Technics in the SL-10. The arm itself was supported on resin bearings which were said to be less noisy than conventional metal ball types. The motive power for moving the arm came from a pair of miniature BSL (Brushless and Slotless) motors that worked in much the same way as the larger motor that drove – directly – the diecast aluminium alloy platter.

In practice these tonearm motors were the same as those used to drive the capstans of Sony's top cassette decks (such as the TC-K81). Two were employed and linked by a clever epicyclic gear drive that allowed either one of them to drive the tonearm without anything having to be disengaged. One motor was used for fast actions, such as cueing and returning the arm at the end of a record, while the other moved it during playback.

One intriguing feature of the PS-X800 was that the tracking motor ran at a continuous minimum speed while the record played, rather than in the small jumps normally observed with linear-tracking decks. The speed was calculated as the arm progressed and Sony claimed that this more closely mirrored the movement of the cutter head when the record was being made.

Other aspects of the PS-X800 followed the traditional Sony practice of the era. The plinth was made from SBMC (Sony Bulk Moulding Compound) resin to which all the parts were rigidly mounted. Adjustable feet with elastomeric inserts were the only form of isolation offered, other than the near 12kg weight of the machine as a whole. The BSL spindle motor was quartz-locked and ran at two speeds, neither of which could be varied by the user. Finally, a Sony 'Magnadisc' servo pick-up measured the platter's speed. This had a strip of iron-loaded paint around the inside of its edge, which was printed in the factory with a magnetic pattern, much like a recording on a piece of tape. This was then read by a pick-up head in close proximity, clearance being maintained to eliminate the possibility of wear.

Zip Drive

Despite being largely made from synthetic materials, the finish of the PS-X800 is immaculate. True, it doesn't quite have the solidity of a Technics SL-10, but the detailing is superb. As was the fashion at the time, the lid falls short of the front of the plinth leaving the controls exposed. This allows a record to be played in a largely dust-proof atmosphere, and with power cueing there is no need to open the cover until all the listening on that particular side of the disc is concluded.

Like all the PS-X800's functions the cuing works smoothly and silently. The arm moves slowly if just the direction keys are pressed but zips along more smartly if you push the 'fast' key as well. An odd omission, given the level of automation present in the machine, is that speed selection is fully manual, despite it being logic-controlled. A beam of light that shines from the rear of the arm housing and down through slots in the platter will recognise a 7in single, otherwise the turntable will play at 33rpm. To automate this function would surely have been trivial.