Technics SL-10 turntable

Parallel tracking, optical position sensing and all in a slick package no larger than an LP sleeve. It dazzled in its day, but how does this '70s direct-drive deck sound now?

Parallel tracking, optical position sensing and all in a slick package no larger than an LP sleeve. It dazzled in its day, but how does this '70s direct-drive deck sound now?

There is an argument which says that to recover maximum information from any recording the playback system should be as similar as possible to the arrangement with which it was made. For example, a tape deck identical to the one used in the studio should replay the original master tapes with the highest achievable accuracy.

When it comes to LP records this simple principle is often forgotten. All are cut using a head that moves tangentially across the disc's surface, yet the pick-up of the typical turntable describes an arc, which is a quite different geometry. The conventional radial turntable may be simple to make, but the economies of scale resulting from big production runs allow advanced techniques, such as electronically controlled linear tracking, to be employed.

Derived Not Derided

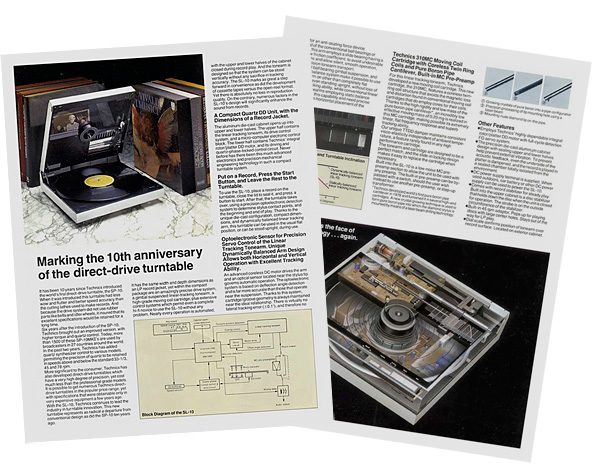

The two most famous linear-tracking turntables are the B&O Beogram 4000 [HFN Jun '14] and the Technics SL-10, as reviewed here. Both were groundbreaking, state-of-the-art products of their eras and both began series that would eventually include a wide range of derived types.

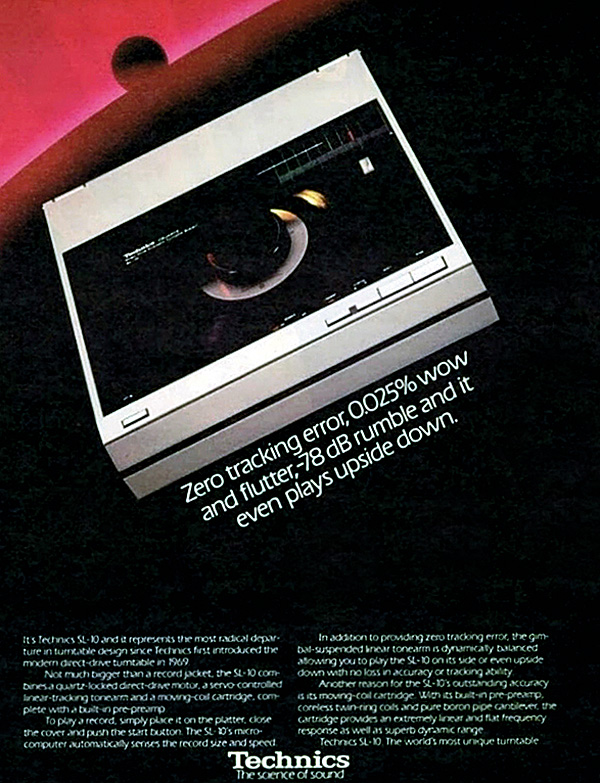

The SL-10 was introduced late in 1979, at the absolute peak of the Japanese hi-fi industry's power. As well as being the first turntable with linear tracking from the Matsushita group, it also pioneered the idea of a complete turntable system with a footprint the same size as an LP in its sleeve. So compelling was this idea that nearly every Japanese manufacturer was soon producing a lookalike copy of some description. While most of these were basic products for the casual user, the SL-10 was built for the discerning listener and used the best available materials and technology to give top audio performance. Each half of the casing was die cast in alloy and machined to fine tolerances. The turntable motor was a direct-drive type with its rotor integral with the platter, controlled by a quartz-locked servo. Operation of all of the functions was fully automatic, sequenced by a built-in microprocessor, while the arm came tipped with an EPC-310MC moving-coil cartridge, the preamplifier for which was built into the plinth. No expense had been spared and no corners cut. The Technics SL-10 was intended to rival the performance of the very best.

Squeeze Box

The challenge of packing this functionality into such a small unit was overcome by using all of the available space within the cabinet. The plinth contained the power supply, the turntable motor and its attendant circuitry and the MC head amplifier. The complete arm mechanism, the tracking servo and the microprocessor were located in the lid, the two parts being connected together by flexible cables running through the hinges. As was typical for a Japanese design, isolation from external vibrations was provided only by simple sprung feet, although the unit's high mass (6.5kg) and rigid construction helped to make these effective. Measures taken to keep internal resonances under control included a stiff arm whose effective length was just 105mm, a record clamp built into the lid and a dynamically balanced platter with rubber mats bonded permanently to both sides. The mat underneath even included moulded-in turbine blades in order to help keep the hard-working circuitry cool.

Off It Goes...

The SL-10 was an instant hit with demand far outstripping supply. Since the factory couldn't make them fast enough, a version that was easier to produce was soon added to the range. This was the SL-7, which sold in vast quantities. The simplification of the structure and electronics did nothing to harm the performance. In fact it has been suggested that the SL-7 is actually the better sounding of the two compact turntables.

One improvement is unquestionable: the occasionally audible 'bump-thump' of the SL-10's tracking servo was cured in the SL-7 by the use of a different type of motor. Also introduced were the SL-15 with programmable track selection but no MC cartridge and the vertically mounted SL-V5. At the other end of the range, the SL-5 was a stripped-out budget model without the alloy cabinet and the quartz-locked motor, which still managed to be a decent turntable for a very reasonable price. Beneath this, the SL-3 retained the square outline and linear-tracking arm but was belt-driven.

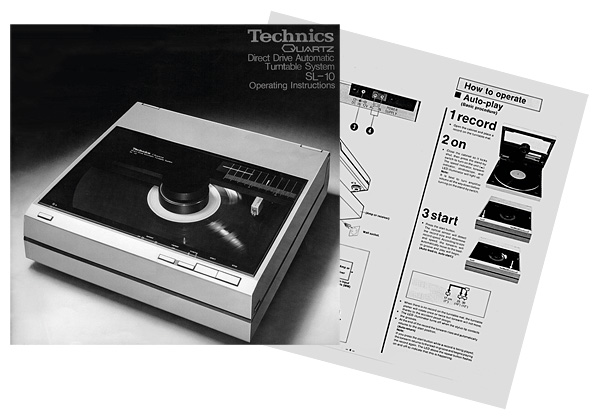

Using the SL-10 is as simple as any turntable can be. After pressing the two catches at the sides the lid opens, leaving unobstructed access to the platter. With a record in place and the lid shut, all one has to do is to press play and off it goes. There is no chance of getting tangled up with the arm and no possibility of damaging the stylus; it is so simple that a child can do it.

On Command

Once in operation, cueing is power operated using the play and stop keys, their functions changing to forward and reverse once the arm is lifted. A lamp inside the lid comes on whenever the arm is lifted to make the record surface visible for track selection, though it has to be said that the heavily tinted window above makes it difficult to see the surface clearly.

Playback stops on command, when the record ends or when the lid is opened. The internal logic turns off the motor and lifts and returns the arm as soon as the lid is opened even a crack, so it is quite safe to stop the machine at any time like this.

The T4P plug-in cartridge system also makes setting the turntable up easy. Placement is not at all critical (the deck will even work tipped up on its side!) and since all T4P cartridges have the same overhang and weight there is no need to adjust the arm when fitting the pick-up – the system was originally conceived to encourage easy replacement and upgrade.

The quartz-locked motor runs up to speed instantly and provides excellent speed stability – a tiny strobe ring is built into the top of the record clamp and its bars never appeared anything other than stationary. There is no facility to fine tune the speed, but the automatic selection of 33.33rpm for 12in records and 45rpm for 7in ones can be overridden so that 7in EPs and 12in singles can be played.