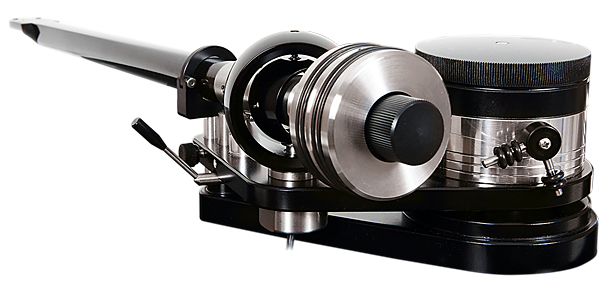

VPI HW-40 Anniversary Turntable Sidebar: 3D Vision

Arguably, the biggest leaps in tonearm performance have been associated with improved materials and manufacturing – specifically the introduction of SME's one-piece diecast magnesium Series V tonearm along with Rega's rather more affordable RB300 in 1983 [see Audio Milestones, HFN Nov '12]. It took two years to develop the diecasting for Rega's silicon alloy tube and bearing housing, but in 2013 VPI's Mat Weisfeld was able to prototype and produce a variant on the 'jointless' tonearm with far greater ease using a 3D printer. 'Using 3D printing techniques seemed the best approach since it could all be one piece and well damped,' said Mat.

Because 3D printing extrudes the material outwardly – here using a high-temperature laser to build 0.001in layers of non-crystalline epoxy resin – the headshell, tonearm tube and counterweight extension can be created as a single arm wand. VPI's uni-pivot arms also include the fingerlift and pivot housing in the 3D printing but the 12in 'Fatboy' tube is supported within a Japanese-sourced gimbal bearing and has a detachable fingerlift. PM