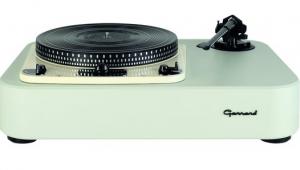

SME Model 60/Series VA Turntable

This icon of British hi-fi is typically sparing in its celebration of milestones, but SME's Diamond jubilee demanded something very special indeed. And here it is...

This icon of British hi-fi is typically sparing in its celebration of milestones, but SME's Diamond jubilee demanded something very special indeed. And here it is...

If the engineers at SME felt the need for a motivational quote or two while working on the company's new turntable, Rolls-Royce co-founder Sir Henry Royce's 'Take the best that exists and make it better' would have been a good choice. This summed up the challenge facing the UK company in designing a successor to the previous Model 30 flagship – the result is the £49,950 SME Model 60, and it has a tough act to follow.

The Model 30, originally released in 1989, and its 30/2 and 30/12 'tweaks', are regarded by some as the pinnacle of turntable engineering, and the fact the arrival of SME's new flagship has been over 30 years in the making suggests the company wasn't in any rush to topple its own crown. (For those wondering what happened to Models 40 and 50, the 60's appellation celebrates the diamond anniversary of SME's first hi-fi product, the 3009 tonearm of 1959.)

Perfect Platter?

It's therefore no surprise that the Model 60 contains a mix of old and new technologies. The platter, for example, remains unchanged, with SME asserting that it could find no way to meaningfully improve upon the design of the '30. It is still slightly over-sized at 330mm, weighs 7.5kg, and has a machined, acoustically inert upper surface to support the record. Also unchanged are the record washer and the screw-down clamp.

The two-tier chassis, now with elegant curves, is made from aluminium alloy and sits on four height-adjustable feet that are decoupled from the main, lower chassis by an internal multi-point isolation system. Also fitted to this chassis are the motor mounting pod, and a connection box at the rear that serves to terminate the tonearm wiring to the output phono sockets.

One tower at each corner supports the upper (sub)chassis, using an ostensibly similar system to that of the Model 30/2 but one that has been refined and improved. Suspension is still achieved through a number of rubber support bands but, on the new Model 60, the way in which they 'carry' the subchassis has been inverted, so they describe a wider circle at the top, rather than at the bottom. The number of bands in each corner has also increased from 12 to 15, while the supporting towers no longer incorporate a separate fluid damper in each column, additional bands instead providing lateral anchorage and damping.

The Model 60's bearing is still a high-carbon steel type spinning on a precision ball bearing, ably assisted by sintered bronze bushings. What is new, however, is a silicon fluid-filled damping bath at the base of the bearing housing. This aims to absorb any microscopic resonances generated by the rotating mass of the main bearing/spindle/platter assembly. In addition, the bearing housing has been lowered within the upper (sub)chassis, so the platter sits closer to the top plate.

Motive power to the platter is provided by a 24V AC motor, replacing the DC type used for the 30/2. This is a necessary update, says SME, to guarantee the desired accuracy over speed control. Power to this motor is provided by not one, but two external units. The first houses a large transformer and offers an unregulated DC supply via an umbilical to the second box. Here it's smoothed and regulated, supplying both the DSP-based frequency generator and main synchronous output.

This latter chassis also hosts the on/off and speed change buttons, plus rotary pitch control. Be aware that SME advises against switching speed from 33.3rpm to 45rpm, or vice versa, on the fly – you need to stop the deck, change the speed and re-start.

Total Control

The Model 60's speed controller employs a microprocessor to generate two independent sine wave signals that are closely controlled in amplitude, frequency and phase. SME claims this provides 'total control over the way the custom AC synchronous motor behaves, and enables precise tuning of the motor to obtain the best possible performance'.

Both transformer and control box are machined from solid aluminium and are as meticulously engineered as the deck itself. To wire everything together, the Model 60 is supplied with a Siltech Explorer mains cable and shielded Siltech Silver Gold connection leads terminated with latching LEMO connectors.

A-Class Arm

Perhaps the most notable addition to the Model 60 is a new tonearm, designated 'Series VA' – the 'Advanced' iteration of the longstanding Series V. This features a bearing yoke still made from a magnesium/aluminium alloy, but the arm tube is no longer metal. Instead it is hewn from an 'advanced polymer resin', and not 3D-printed but machined from a solid block just like the magnesium alloy armtube of the standard Series V.

Other upgrades include the shape of the tube, which now has a more rigid 'tri-lobular' cross-section rather than one that's cone-shaped. Also new is the semi-circular support cradle under the arm. The old arm lock was arguably more secure but could leave a mark on the matt finish of the armtube. Never again…

Furthermore, the arm is now directly wired into the RCA output panel on the rear of the deck, and the swivelling 90° DIN connection on the base of the Series V is absent. So, if you must ask… the Series VA, like the Series V, will only be available with SME's turntables and not sold separately.