AVID Volvere SP Turntable

Inspired by the flagship Acutus turntable, and bucking the trend for unsuspended decks with socially-distanced motors, the Volvere SP also comes with a familiar tonearm

Inspired by the flagship Acutus turntable, and bucking the trend for unsuspended decks with socially-distanced motors, the Volvere SP also comes with a familiar tonearm

Given that pretty much every component AVID has ever offered is still in production, it's clear company owner Conrad Mas does not chop and change designs on a whim. So it's no surprise that when it comes to turntables AVID has largely stuck with the thinking behind its very first deck, the Acutus, which was launched in 1999.

The same philosophy of high-mass platter, suspended subchassis and torquey motor can be seen at work in the latest version of AVID's midrange turntable, the £5500 Volvere SP. The first iteration of the Volvere deck was actually the firm's third ever product, but the 'SP' appellation signifies it now benefits from the fine speed control offered by its DSP-governed PSU.

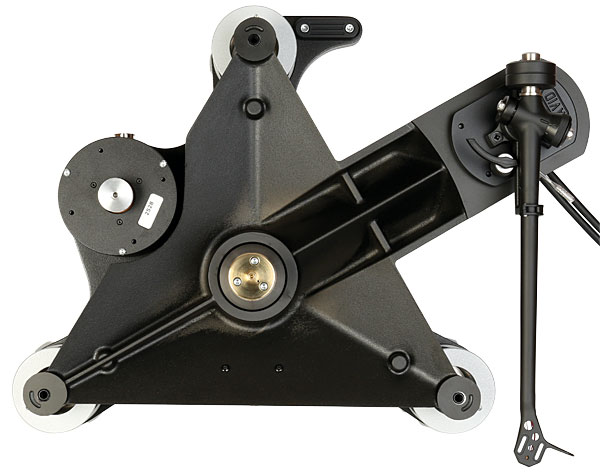

Available in either silver or black, the Volvere SP features a cast alloy subchassis with carefully machined ridges to minimise vibration. This subchassis sports three legs, each of which sits in a spring located on the lower base. In fact, the legs sit in 'cups' in the centre of the springs, so the coils extend downwards in normal use.

Handy Feature

Experience suggests that this arrangement makes for a much more stable set-up than when compressed springs are used and requires less regular tweaking. In addition, three sturdy O-rings locate around each suspension turret onto pegs on the subchassis, which limits lateral movement.

The subchassis contains the bearing and an outrigger on which to mount a tonearm. As a result, the deck does not offer interchangeable armboards but comes pre-drilled for a standard 9in SME fitting. Adapters that allow arms with standard Linn or Rega mounts to fit this are readily available from AVID.

A handy feature is that this subchassis will sit securely on its mounting legs prior to fitment into the springs. This greatly aids set-up as it means that the arm and cartridge can be fitted and aligned before the whole thing is lowered onto the main lower base. After all, there are few things more frustrating than trying to align a cartridge on a bouncing turntable!

As for the bearing, this is an inverted type, meaning it has a central spindle on which sits a ball in a small dimple. This makes contact with a sapphire thrust pad on the underside of the main bearing when this is lowered over it. The inherent stability of this design means that only one bush is required lower down the bearing shaft. This is made from sintered bronze and is essentially self-lubricating. Indeed, AVID confidently claims that no additional lubrication is required for ten years under normal use.

Speed Bump

The outboard PSU generates a stable supply for the AC motor, and can be altered in frequency to not only allow push-button speed change between 33.3 and 45rpm, but also permit the fine tuning of each speed. The PSU weighs in at 2.2kg and its front panel features dainty pushbuttons for turntable start/stop and speed change, alongside a large rotary knob for main power on/off. A high-quality internal toroidal transformer provides the main supply, so it does not rely on the cheap 'wall wart' mains adapters that are so common these days.

The Volvere SP's motor is made by French manufacturer Crouzet and this drives the platter via two precision circular cross-section belts. As mentioned in PM's Lab Report, this whips the 6.7kg platter up to speed remarkably quickly. The platter is topped by a fixed cork mat, and as part of AVID's vibration-control measures a supplied screw-down record clamp ensures the LP can be mated snugly to it.

So far so good then, but the tricky bit comes when you need to fit the twin belts. With the subchassis and base mated, the belts are wrapped around the main platter drive hub, and a pin must be fitted into a hole on the underside of the platter. The platter is then lowered onto the bearing and the belts persuaded off the pin and onto the pulley, before finally the pin is removed. It sounds easy when you write it down, but it took me eight attempts.